Made to order from 1 to 10,000 pieces on demand

One-on-one support service Response within 12 hours

In-house machine shop, 24/7 operations, Quick turnaround

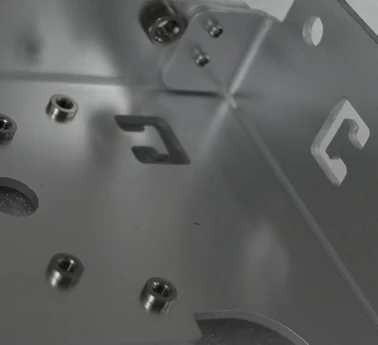

Wide range of machining technicals. Tight tolerances, Finer surface finishes.

ISO 9001:2015 certified 100% part inspection

Our Sheet Metal Fabrication Services

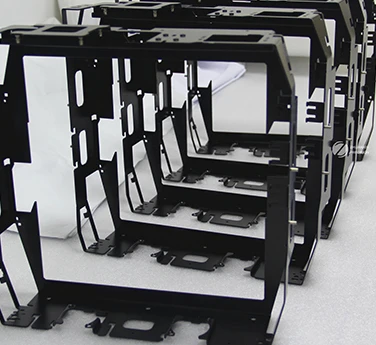

IDEAL'S custom sheet metal prototyping services offer a fast and cost-effective solution for your projects. Services including bending, punching, cutting standard gauge metal for both prototypes and low volume production runs. Sheet metal fabrication produces durable, end-use metal parts with a wide selection of materials and finishes that meet your specifications, for a variety of industries like: Automotive, Medical device, Aerospace, electronics, energy and robotics.

Advantages of Sheet Metal Fabrication

Wide Range of Material and Surface Finish Options

Suitable for various metals, including steel, aluminum, stainless steel, copper, and brass. Offers multiple surface finishing options, including powder coating, anodizing, painting, and polishing.

Speed and Efficiency

Quick turnaround times for producing parts, particularly with automated processes. Faster design-to-production cycles due to efficient manufacturing processes and advanced machinery.

Scalability

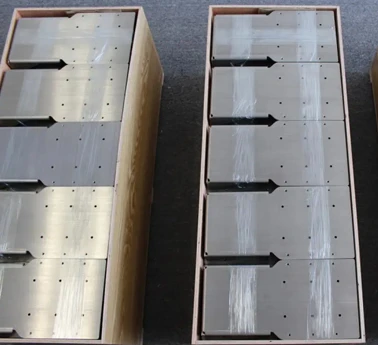

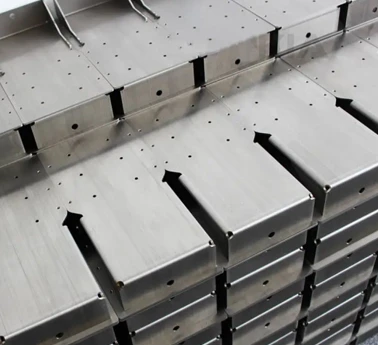

Effective for both small and large-scale production, from prototypes to mass production.

Design Flexibility

Capable of producing intricate and complex designs, including bends, folds, and deep draws, and allows for easy modifications and adjustments during the design phase or after production.

Have any Questions or Suggestions? We would love to help you! Talk to us!

How Sheet Metal Fabrication Works?

Sheet metal fabrication transforms flat metal sheets into precise, durable components through a series of controlled steps: material selection, cutting, forming, joining, machining, finishing, and assembly. By managing each stage with strict quality standards, IDEAL ensures reliable parts for a wide range of applications.

Material Selection, Design & Planning

Metal Type: Steel, aluminum, stainless steel, copper, brass.

Thickness and Gauge: Defined by strength and flexibility needs.

Blueprints and CAD Models: Detailed designs and cutting patterns for accuracy and efficiency.

Cutting Patterns: Straight cuts for large sheets.

Cutting & Forming

Shearing: Straight cuts for large sheets into smaller pieces or basic shapes.

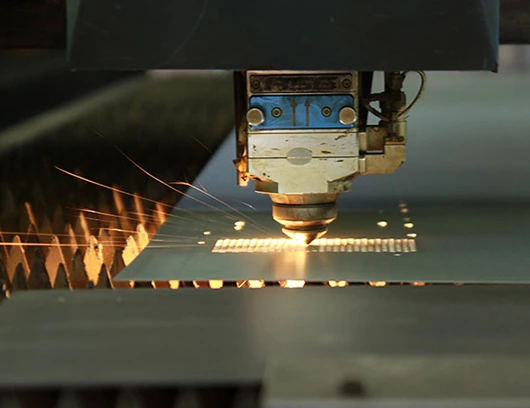

Laser & Waterjet & Plasma Cutting: High-precision or thick-material cutting. Plasma cutting ideal for thicker sheets and less precision; Waterjet ideal for thick or sensitive materials without heat; Laser cutting ideal for intricate designs and high precision.

Bending: Press brakes create angles and curves.

Stamping & Deep Drawing: Shape or emboss sheets; form complex, hollow parts.

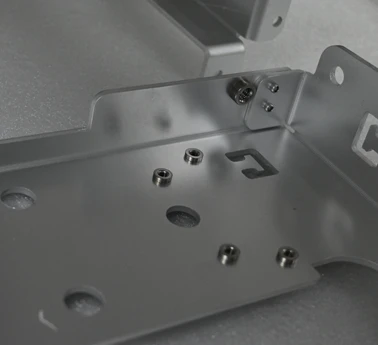

Joining & Secondary Machining

Welding (MIG, TIG, Spot): Fuses parts permanently.

Riveting, Screws & Bolts: Joins metal parts by inserting and fastening rivets. Mechanical fastening for adjustability.

Drilling & Milling: Add holes, refine shapes, or machine features.

Quality Control, Assembly

Inspection & Texting: Dimensional checks includes visual inspection and dimensional checks, and performance validation, such as strength tests or corrosion resistance tests.

Assembly: Combine parts through welding, fastening, or riveting.

Sheet Metal Fabrication Service We Are Offering

Laser Cutting

A high-density energy beam precisely evaporates material, producing narrow kerfs and high-quality cuts. Suitable for plain steel, stainless steel, spring steel, and aluminum (with higher power).

Types of Lasers and Their Cutting Capabilities

CO2 Lasers: Versatile; cut metals, plastics, and wood. Typical thickness: mild steel ≤25 mm, stainless steel ≤12 mm, aluminum ≤6 mm, acrylic/wood ≤50 mm.

Fiber Lasers: Fast and precise for metals. Typical thickness: mild steel ≤30 mm, stainless steel ≤20 mm, aluminum ≤12 mm.

Nd: High-precision, small-scale cutting (medical/industrial). Typical thickness: metals ≤6 mm.

Typical Tolerances

General Tolerances: Typically range from ±0.1 mm to ±0.5 mm. Thinner materials allow for tighter tolerances due to less heat distortion and better beam focus.

High Precision Tolerances: As tight as ±0.05 mm or better. Achieving these tight tolerances often requires advanced laser cutting systems and careful control of process parameters.

More Resources:

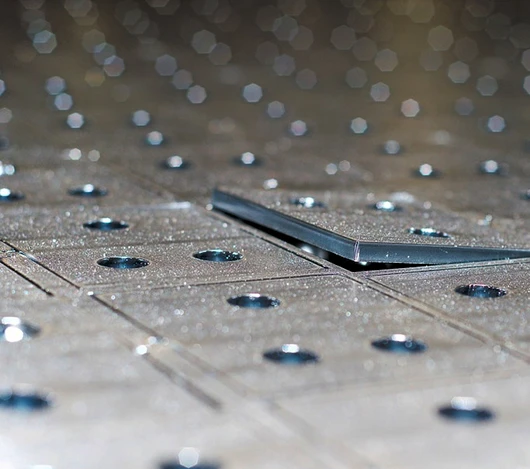

Punching

Punching is a widely used manufacturing process that involves creating holes or shapes in sheet metal or other materials using a punch and die.

Types of Punching and Their Capabilities

Mechanical Punching: Flywheel-driven, high-speed, high-volume, standard shapes.

Hydraulic Punching: Greater control, ideal for thick or complex shapes.

Pneumatic Punching: Air-driven, light-duty, simple shapes.

Laser Punching: Combines punching with laser cutting for precision and versatility.

General Tolerances

Standard Tolerances: ±0.1–0.5 mm, with tighter control on thinner materials.

High Precision Tolerances: Up to ±0.05 mm with advanced equipment and tooling.

Bending

A core metalworking process that forms materials into angles or curves, widely used to produce components across industries from construction to electronics.

Types of Bending

Air Bending: Bend angle set by punch depth and springback; versatile for various angles and radii.

Bottoming (or Coining): Punch wipes across material; best for thin sheets or large-radius bends.

Wipe Bending: Punch wipes across material; best for thin sheets or large-radius bends.

Rotary Bending: Rotating tool forms smooth bends; ideal for tubes and profiles.

Roll Bending: Rollers gradually curve material; suited for large-radius or cylindrical shapes.

Press Brake Bending: Punch and die form bends; widely used, precise for standard angles.

General Tolerances

Standard Tolerances: ±0.5–1.0 mm, affected by material thickness, hardness, and springback.

High Precision Tolerances: ±0.2–0.5 mm for critical applications, achievable with advanced equipment and strict process control.

Stamping

A high-speed process that shapes sheet metal into parts using a press and die, ideal for precise, high-volume production.

Types of Stamping and Their Capabilities

Blanking: Removes a piece of material (blank) from a larger sheet.

Punching: Creates holes, slots, or patterns in panels, brackets, and components.

Embossing: Forms raised or recessed designs by pressing material between a die and counter-die, used for decoration, texturing, and branding.

Forming: Shapes material into 3D bends, curves, or complex geometries; commonly used for panels, enclosures, and casings.

Drawing: Pulls the material into a die cavity to create deep or complex shapes. This technique stretches the material to form hollow parts.

Progressive Die Stamping & Compound Die Stamping: Progressive Die Stamping is multiple operations in sequence; efficient for high-volume complex parts; Compound Die Stamping is multiple operations in one stroke; ideal for parts with combined features.

Limitations of Stamping

Initial Tooling Costs: High initial investment in tooling and dies, which can be a barrier for low-volume production.

Material Limitations: Some materials may be challenging to stamp due to hardness or brittleness.

Design Constraints: Complex designs may require multiple stages or specialized tooling, increasing complexity and cost.

Welding and Assembling

IDEAL specializes in multiple welding processes, including TIG and MIG welding.

Final assembly is completed through methods such as welding, riveting, threaded fasteners, adhesives, and, when needed, additional bending.

TIG Welding

Also know as Gas Tungsten Arc Welding (GTAW), TIG welding is arc welding process involving the use of a non-consumable tungsten electrode in order to deliver a weld. With stainless steel, this type of welding can be done with our without the use of a filler wire.

MIG Welding

MIG welding entails the use of a filler metal in the form of wire. This wire is fed through the welding torch and delivers a higher welding speed than that seen in TIG Welding.

More Resources:

Why Choose Sheet Metal Fabrication From IDEAL?

Expert Project Management. IDEAL offers a number of fabrication processes, and meeting ISO 9001:2008 standards. Our skilled engineers and technicians provide timely communication and updates, ensuring project management from initial design for manufacturability (DFM) to shipment.

Wide range of capabilities. Including CNC bending, laser cutting, welding, press fitting, stamping and post finishing.

24/7 Operation and Flexibility. IDEAL works closely with clients to provide customized machining solutions tailored to specific design requirements, offering flexibility in design modifications, prototyping, and iterative improvements.

Integrated Supply Chain and Global Logistics. With access to a comprehensive supply chain network facilitates sourcing of materals and components streamlining the production process. Our location in Guangdong Province( Shenzhen) enable effcient shipping of finished parts worldwide.

Sheet Metal Materials

Sheet metal fabrication uses various materials, each offering distinct properties suited for different applications. Here are some commonly used sheet metal materials:s

| Low Carbon Steel (Mild Steel) | Stainless Steel 441 | Titanium Alloys |

| Medium Carbon Steel | Stainless Steel 410 | Hot-Dip Galvanized Steel |

| High Carbon Steel | Stainless Steel 420 | Electro-Galvanized Steel |

| Alloy Steel 4130 | 17-4 PH | High-speed Steel |

| Alloy Steel 4140 | 15-5 PH | Cold-work Steel |

| Nickel-Chromium Steel 4340 | 1000 series (pure aluminum) | Hot-work Steel |

| Stainless Steel 304 | 3000 series (aluminum-manganese) | Spring Steel |

| Stainless Steel 316 | 5000 series (aluminum-magnesium) | Nickel Alloy |

| Stainless Steel 321 | 6000 series (aluminum-silicon-magnesium) | Tool Steel D2 |

| Stainless Steel 430 | Bronze | Tool Steel A2 |

| Stainless Steel 409 | Brass |

Our Maxime Size Range of Your Machine Ability

Maximum Dimensions 990.6mm x 1,193.8mm

Minimum Dimensions: Flat Part 6.5x 6.5 (mm); Formed Parts 13 x 13 (mm)

Overview of Sheet Metal Post-Processing

Surface finishing enhances appearance, durability, and performance of sheet metal components. IDEAL offers the following processes.

Polishing & Deburring & Grinding: Smooth surfaces, remove burrs and imperfections.

Sandblasting: Clean and texture surfaces with high-pressure abrasives.

Chemical Etching: Using acid or other chemicals to remove material and create a textured or patterned surface.

Electroplating: Apply thin metal coatings (e.g., chromium, nickel, gold) for corrosion resistance and appearance.

Anodizing: Convert aluminum surface to oxide layer for wear and corrosion resistance.

Powder Coating: Durable heat-cured finish with strong corrosion and weather protection.

Painting: Protective and aesthetic coating (spray, roller, or dip).

Passivation: Acid treatment (mainly for stainless steel) to enhance corrosion resistance.

Hot-Dip Galvanizing: Molten zinc coating for strong outdoor/structural protection.

Laser Marking: Using a laser to etch or engrave patterns, text, or logos onto the metal surface.

Hardware Insertion: Secondary process for adding PEM inserts, rivets, standoffs, clinch nuts, studs, pins, and panel fasteners.

Tapping and Countersinking: Tapping and countersinking of holes on a sheet metal design can help integrate hardware. Metric tapped holes available between M2 and M12.

Welding & Assembly: Gas metal arc welding (MIG) and gas tungsten arc welding (TIG) are possible on sheet metal parts at IDEAL.

Sheet Metal Fabrication Tolerances

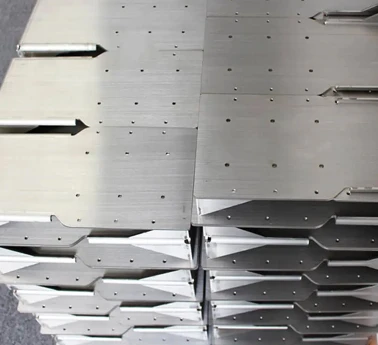

IDEAL delivers high-quality fabrications ranging from wall dispensers and protective covers to radar housings, generator cabinets, and brackets. To ensure consistency, we leverage advanced technologies including CNC laser cutting, punching, bending, robotic welding, and automated/manual powder coating.

Since tolerances directly affect cost—overly tight ones can double or triple expenses—IDEAL offers multiple tolerance levels. This approach reduces costs where broader tolerances are acceptable, while maintaining precision and quality where it matters most.

Here’s how tolerance grades impact pricing:

Grade A - Tightest tolerances

- Higher scrap rate allowance

- Greater and more frequent QC inspections

- Better tooling and jigs

- More specialized QC equipment

Grade B - Standard tolerances

- Standard scrap rate

- Standard QA inspections

- Standard tooling

- Standard QC equipment

Grade C - Broader tolerances

- Low scrap rate allowances

- Random sample QC inspections

- Possible low cost tooling

- Limited QC equipment required

Sheet Metal FAQS

Q: How To Choose From Laser Cutting, Water Jet Cutting Or Plasma Cutting?

A:

Evaluate these factors based on your specific project requirements to select the most suitable cutting method.

Material Thickness: Laser cutting excels with thinner materials, while water jet and plasma cutting handle thicker materials better.

Precision: Laser cutting provides the highest precision and cleanest edges.

Heat Sensitivity: Water jet cutting avoids heat distortion, unlike plasma and laser cutting.

Cost: Plasma cutting is generally more cost-effective for thicker materials, while laser cutting can be more expensive but offers high precision.

Q: Does It Cost more To Use Multiple Sheet Metal Forming Processes?

A:

Using multiple processes like bending and stamping can increase costs due to additional tooling, setup time, and potential material handling. It can, depending on the complexity and requirements of each process. In general, most sheet metal parts demand a combination of forming processes, and this will not increase the price by a drastic amount.

Q: How Does The Choice Of Material Affect Costs?

A:

The choice of material significantly impacts costs in several ways:

Raw Material Costs: Different metals have varying base prices. For instance, stainless steel is generally more expensive than mild steel due to its alloying elements and processing requirements.

Processing and Fabrication: Some materials are harder to work with than others. For example, aluminum is often easier to cut and bend compared to harder metals like titanium, which may require specialized equipment and techniques, increasing fabrication costs.

Tooling and Equipment: Different materials may require different tooling or modifications to existing equipment. For instance, harder metals can cause more wear on tools, necessitating more frequent replacements or upgrades.

Finishing and Treatment: Certain materials might need additional finishing treatments (like anodizing for aluminum or passivation for stainless steel) to achieve desired properties or aesthetics, which can add to the cost.

Material Waste: Some materials may result in more waste during cutting or forming processes. For example, thicker materials might require more trimming, which increases material costs.

Transportation and Handling: Heavier or bulkier materials can incur higher shipping and handling costs, especially if they require special packaging or equipment to move.

Q: What Are The Common Techniques Used For Sheet Metal Machining?

A:

Common techniques include:

1. Cutting: Methods like shearing, laser cutting, and water jet cutting to shape the metal.

2. Bending: Using presses or brake machines to form angles and curves.

3. Stamping: Applying pressure to a die to create complex shapes and patterns.

4. Welding: Joining metal pieces using heat and/or pressure.

5. Punching: Creating holes or shapes by punching out material from the sheet.

Request Your Free Sheet Metal

Our improved algorithm decreases Sheet Metal Machining quotation times by up to 90%. Most quotes are delivered within 24 hrs. and usually much less, depending on project details.

Your customer support partner will contact you directly to ensure you've received and understand all aspects of your quotation and to answer any questions you may have.

Sheet Metal Fabrication Cases

Quickly and costly get your molded parts with the production-grade material and technology process by using the rapid tooling,for low volume rapid injection molding.

See What Our Custom Say

My experience working with Fay was great. Clear communication that put me at ease. Very easy to order these parts. Great quality and werecieved exactly what we were expecting - Followed the engineered drawings precisely. Theproduct arrived well packaged, and precisely to spec.

Thank you very much for your consideration and problem solving. lt says a lot about your companyand feel comfortable working with you moving forward.

Chris

R&D Manager

IDEAL was able to deliver an accurate and quick service for high quality CNC parts. We inspected the parts, everything was within tolerance in terms of dimensions, and the surface finish on the machined faces is really good. IDEAL has always given us exactly what we needed.

Dennis J.

Engineer

Partnering with IDEAL has transformed our production process. Their precision, reliability, and commitment toquality have been game-changers for us. We've seen a remarkable improvement in efficiency and productquality, allowing us to meet our customers' demands better than ever. IDEAL's team truly understands oulneeds and consistently delivers beyond our expectations.

Jennie Elp.

Senior Mechanical Designer

I cannot express to you how happy I am to do business with you, the parts are flawless! The quality is exactly how I hoped it would be! Please give the highest regards to the CNC programmer(s) that handled the parts! And I also thank you for the excellent packaging!

Latest News

Powder Coating Thickness: Standards Measurement and Best Practices

Jan. 12, 2026

Powder Coating Thickness: Standards Measurement and Best Practices

Get Your Parts Into Production Today!

Meeting Your Needs, Solving Your Problems - We're Here to Make CNC Machining Hassle-Free!

GET IN TOUCH WITH US

Navigation

RESOURCE

Contact Us

Tel: 0755-36957776

E-mail: info@idealrp.com

Skype: +86 135 2877 3620

Whatsapp: +86 135 2877 3620

Add.: Shenghua Building, Songgang, Bao'an,Shenzhen 518105

Add.: Room 4, 16/F, Ho King Commercial Building, 2-16 Fa Yuen Street, Mong Kok, Kowloon, Hong Kong