Aug. 24, 2021

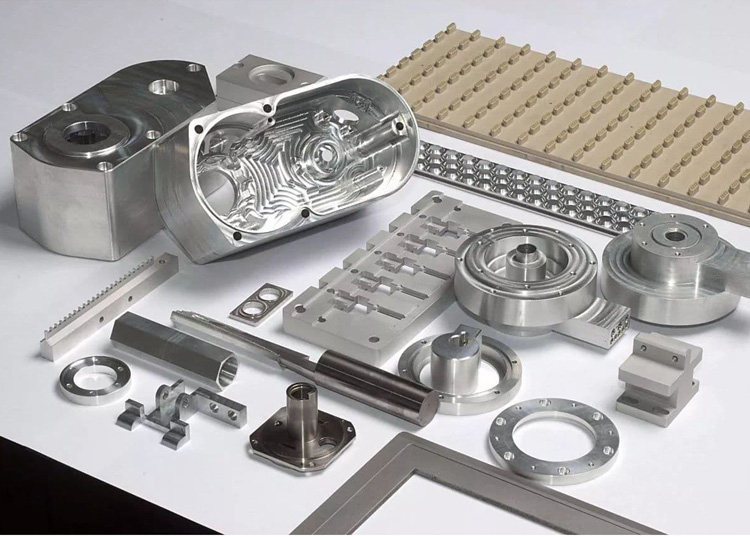

The excellent quality and precise features we get on our CNC parts come with a price and, mind you, it is not that cheap. That is why when planning on fabricating your custom machined parts, you should learn one crucial element, and it is the economics behind CNC machining. This element sheds light on certain factors causing a significant shoot up in the price for producing parts. Being aware of these factors will lead you to a clearer understanding of the costing side for CNC production, which will eventually help you save money on fabricating your parts.

Keep reading as we try our best to walk you through the major factors that affect the CNC machining cost, as well as the different tips in minimizing it.

3 Main Factors That Affect The CNC Machining Cost

You might be wondering why one part (part A) is significantly more expensive than the other part (part B) while in fact, part B is smaller than part A? In the CNC machining industry, pricing is not solely reliant on size, like most products. The price to fabricate CNC parts is often a combination of different factors, which can be reduced to three major factors: part complexity, feature requirements, and material used.

1. Part Complexity

Your part design will fall in this category. Certain geometries and features are harder to achieve and require special tooling and extensive programming before they could be made. That is why as a rule of thumb, the more complex your parts are, the more expensive it gets. Complex parts are harder to achieve because they require extraordinary measures like longer machining time, higher operator skill level, multiple machining processes, and special toolings, all of which account for a leveraged operating cost.

2. Dimensional and Finish Requirements

Part callouts such as dimensional limits, feature controls, and finish requirements can drastically affect the pricing of CNC machined parts. It is because parts with tight tolerances will require a fabricator to have a more intensive series of machining operations in assuring part compliance per requirements set. In other words, the fabricators will then need additional machining processes and rigorous sets of inspections that require special gauges and highly skilled operators.

3. Material Used

The material needed for your part can affect the price of machining in different aspects, and these are:

Size- Machining large parts would require using expensive tools, special holding fixtures, and extra effort. That is why it can be quite difficult to machine large parts and would usually take up longer machining time than those of the smaller components.

Machinability- Not all materials have the same behavior to the cutting action happening during the machining operation. Materials with high machinability index like brass and aluminum would be very easy to cut and cost less than materials with low machinability like steel.

7 Helpful Tips To Save CNC Machining Cost

Now that you have learned about the major factors that affect machining cost, allow us to give you 7 helpful and practical tips to minimize CNC machining cost.

1. Be wise in Material Selection

Base your material selection according to your part’s application. Remember to choose highly machinable materials as much as possible. Use hard materials (e.g., steel, titanium, or other superalloys) only when its mechanical properties are required for an application.

2. Simplify your parts design

As much as possible, you should simplify your parts and focus on a design with practical implications. To minimize machining time, tooling utilization, and machining processes, you should not overcomplicate part features when it is not even relevant to your application. Take note that the price for the part goes up with the complexity of the machined part.

3. Avoid requiring tight tolerances as much as possible

Parts with tighter tolerances are significantly harder to achieve, hence making it expensive. Only control a dimension if it is essential to the part’s overall functionality. One great piece of advice we can give you is to design your part to have one common reference point or datum. This will both help you and the machinist. First, you, to minimize the dimensional controls you need to put on a part, and second, the machinist, to lessen the inspection time.

4. If complexity is inevitable, convert one piece of that complicated part into modular components instead

When one part gets too complex, it is advisable to split one whole part into multiple components to be assembled. This will make machining much easier and simpler. It significantly reduces set-up time, lessens machining operations, and optimizes machining time. This is a strategy commonly used by designers to promote a part’s manufacturability and lessen its fabrication cost.

5. Consider Hole sizes and profiles

When fabricating for your CNC parts, you should ensure that your part features (e.g., holes, contours, slots, threads etc.) can be made with standard toolings commonly available. Custom hole and thread sizes will need special tools, which can be quite expensive. There are many references about standard sizes used in the machining industry available through the internet.

Remember, only use special hole dimensions when required or when necessary for the application.

6. Avoid thin walls and deep cavities for your part design

Thin-walled parts and deep cavities are very challenging to achieve through machining, and they are usually prone to dimensional inaccuracies. These part features tend to cause vibration on the part and sometimes lead to the scrappage of parts. As we say, difficult parts are practically expensive to fabricate.

7. Be wise in planning the machining operations

Lessen your machine operations as much as possible. More operations mean longer set-up and machining time. Strategize your machining technique in such a way that your parts can be achieved with the least changes in set-up.

To minimize the CNC machining cost, you should always consider the part complexity, Dimensional and Finish requirements, and Material used. Always keep in mind that the more difficult a part is fabricated, the more expensive it gets, so to sum it, keep your parts simple as possible.

Search Blog

Thermoforming and Vacuum Forming

Sep. 23, 2021

Steel or Stainless What is the Most Durable Sheet Metal?

Sep. 23, 2021

8 Things You Need to Know About Anodizing Aluminum

Sep. 23, 2021

Sep. 08, 2021

Navigation

Resources

Contact Us

+86 0755 36957776

102, 41 block, No 67 Banggang Road, Dongfang Community, Songgang, Bao'an District, Shenzhen, China

Room 1508, Aran Center Office Seond Phase 15, Nathan Road 625, Kowloon, HongKong