Sep. 08, 2021

Sheet metal welding is a major part of the fabrication process.

Sheet metal components that include two or more components of sheet metal, or profiles and shapes that cannot be cut or formed from a single sheet of material and thereby are impossible to be manufactured as one, may well rely on welding to combine all individual sheet metal components into the final fabricated product.

For complex fabrications that demand high precision, greater control and tight dimensional tolerances the main aim is to avoid distortion and burn-through while ensuring necessary mechanical strength for the application. To do this, metal fabricators need to select the correct welding techniques, employ the latest technology and use skilled and qualified staff .

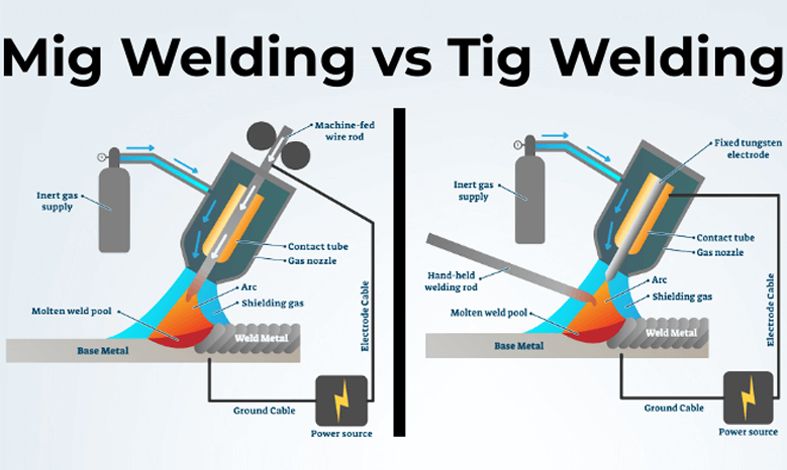

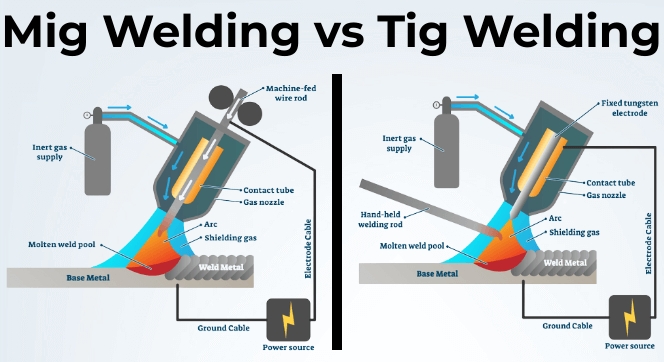

Two of the most common sheet metal welding techniques include MIG (Metal Inert Gas) welding & TIG (Tungsten Inert Gas) welding. This article will explore the main differences between the methods and for what applications metal fabricators are most likely to employ the two methods.

Metal Inert Gas (MIG) welding

Metal Inert Gas (MIG) welding is an arc welding technique whereby a continuous feed of solid wire electrode is fed through a welding gun and into the welding pool at a set speed. This heats the desired area on the sheet metal components, causing it to melt and fuse the metals. A shielding gas also passes through the welding gun to avoid contamination of the welding pool.

MIG welding is suitable for a variety of materials such as mild steel, stainless and aluminium. It is a more than acceptable standard for many fabrication requirements, often favoured for its versatility, speed, and cost-effectiveness.

Tungsten Inert Gas (TIG) welding

Tungsten Inert Gas (TIG) welding is a welding process that uses a non-consumable tungsten electrode to deliver the current to the welding arc. Similar to MIG welding, a shielding gas is used to protect the heated area from contamination.

TIG welding is commonly used for stainless steel components, thin gauge mild steel and non-ferrous metals such as magnesium, copper and aluminium. It is preferred for clean, aesthetic weld results but is significantly more complex operationally and requires a higher level of skill.

When Metal Fabricator use MIG or TIG?

For metal fabricators, successful sheet metal welding includes selecting the appropriate welding method after considering matters such as material, productivity, burn-through, distortion, excessive heat-affected zones, weld appearance and secondary finishing methods.

-Material: MIG welding is suitable for a range of material thicknesses, from thin gauge sheet metal to more substantial structural parts. With TIG welding, the welder can control the heat input so it is often used at lower currents for fragile and soft exotic metals where heat and distortion must be minimal.

-Productivity (Cost & Speed): MIG welding often delivers higher productivity as it is a much quicker process that requires much less time and skill. However, this should not always be assumed. When part of a more comprehensive fabrication project, TIG welding can bypass the need for grinding and other finishing methods which can add to overall costs.

-Strength: Although TIG welding is more complex and slower than comparative approaches, the process provides the welder with greater control which allows for stronger, higher quality welds, particularly important when manufacturers are seeking fabrication of watertight components.

-Component Design: MIG welding is selected when sheet metal components require long welds to be made without pausing, when the weld needs to be applied quickly or if the sheet material is too thick for spot welding. TIG welding delivers a more precise superior finish and is the chosen method when the design includes intricate detail.

-Weld Appearance: Unfortunately, it is impossible to carry out sheet metal welding without leaving a visible burn mark on the surface of the sheet metal. The weld mark can be cleaned or linished, or the part painted or polished, so the joint becomes invisible. As a result, the desired weld appearance is a significant influence of the method used.

If a product specifies a powder-coated finish, for example, a MIG weld will deliver a more than sufficient quality weld with no visible defect. However, if fabrication products require the cleanest, most aesthetic weld possible and will not be undergoing a separate finishing process, TIG will deliver a significantly more attractive result.

As leading custom fabricators, IDEAL offers extensive MIG and TIG welding services.

For more information or to discuss your fabrication project, please get in touch via our contact page or email us at info@idealrp.com

Search Blog

Thermoforming and Vacuum Forming

Sep. 23, 2021

Steel or Stainless What is the Most Durable Sheet Metal?

Sep. 23, 2021

8 Things You Need to Know About Anodizing Aluminum

Sep. 23, 2021

Sep. 08, 2021

Navigation

Resources

Contact Us

+86 0755 36957776

102, 41 block, No 67 Banggang Road, Dongfang Community, Songgang, Bao'an District, Shenzhen, China

Room 1508, Aran Center Office Seond Phase 15, Nathan Road 625, Kowloon, HongKong