Aug. 24, 2021

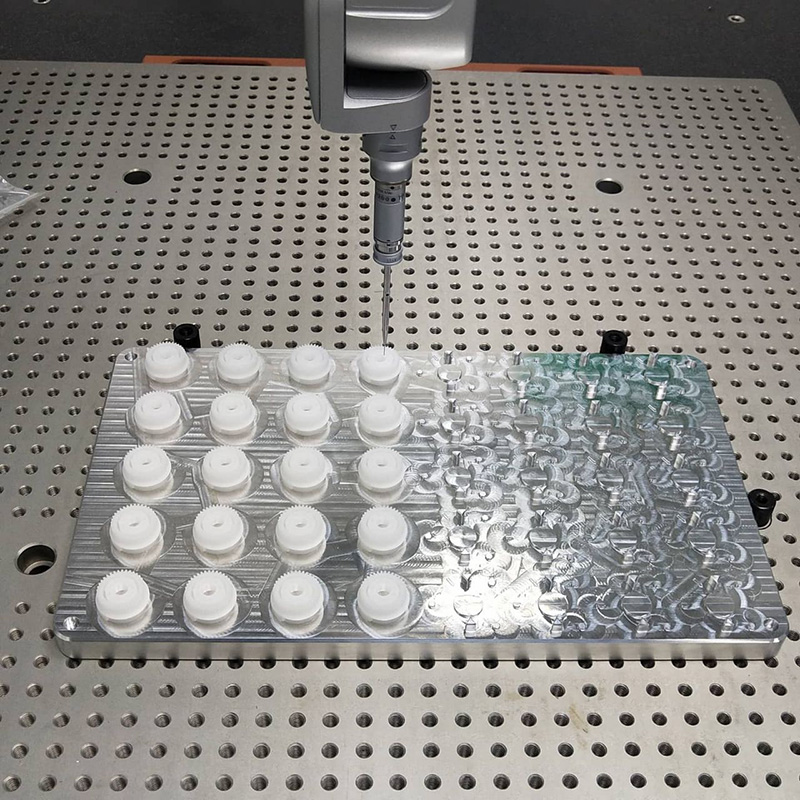

If there is one thing that CNC machining is known for, its accuracy and precision. However, like any other process, there may also be variations in the dimensions of the parts being produced. Factors like material used, spindle alignment, tooling accuracy, work holding rigidity, coolant usage, and shape complexity significantly affect the dimensional accuracy when machining.

Accepting the variability of the dimensions produced, engineers and designers set specific CNC machining tolerances for the parts during the design process to avoid impairing the final product’s functionality and quality. Read on to learn more about machining tolerances, why we need them, and how to achieve a precise and accurate CNC part.

Why Do We Need To Adhere To CNC Machining Tolerances?

CNC machining tolerances are the limits set to identify if a part is acceptable or deemed as scrap. Basically, this is giving perspective on how much room for error you have when machining a part. Why is this so important?

1. Cost Control

Of course, the essence of doing business is minimizing costs as much as possible while still maintaining the needed quality for the parts. Generally, the tighter the tolerance you set, the more expensive it gets. Parts with a very tight machining tolerance call for added processes like grinding or superfinishing. For a less strict tolerance, a part can be finished just through the basic machining processes. What does tolerance have to do with cost?

Defining your tolerances helps avoid overshooting costs for machining a part. Only the critical areas of the part are labeled with tight tolerances. This reduces the cost of components produced by establishing what features matter and what do not.

2. Interchangeability/ repeatability of parts

Most parts being manufactured through machining, in some way, will be interfacing with other machined components for assembly or other purposes. Interchangeability is very critical for fabricating high-volume parts. It allows components to fit any assembly of the same type.

The simplest examples are the mating parts. A shaft is controlled, so it should still fit into the mating part, given any dimension variations. The same is through with the sleeve.

3. Interchangeability/ repeatability of parts

Most parts being manufactured through machining, in some way, will be interfacing with other machined components for assembly or other purposes. Interchangeability is very critical for fabricating high-volume parts. It allows components to fit any assembly of the same type.

The simplest examples are the mating parts. A shaft is controlled, so it should still fit into the mating part, given any dimension variations. The same is through with the sleeve.

4. Maintain the Functionality of parts

Machined parts are controlled by tolerances because some features on a part are vital to its functionality. In many fixturing applications where location and sizes are critical, any variation that is not within tolerance will make a fixture defective and unusable.

What Are The Types Of Tolerances Used In A Machine Shop?

Tolerances in manufacturing drawings are expressed differently, depending on what feature is being controlled and the engineer’s design intent. Below are the most common types of machining tolerances used in the industry:

| Linear dimension range (mm) | Tolerance Class | |||

| F (Fine) | M (Medium) | C (Coarse) | V (Very Coarse) | |

| 0.5 up to 3 | ±0.05 | ±0.1 | ±0.2 | - |

| Over 3 up to 6 | ±0.05 | ±0.1 | ±0.3 | ±0.5 |

| Over 6 up to 30 | ±0.1 | ±0.2 | ±0.5 | ±1.0 |

| Over 30 up to 120 | ±0.15 | ±0.3 | ±0.8 | ±1.5 |

| Over 120 up to 400 | ±0.2 | ±0.5 | ±1.2 | ±2.5 |

| Over 400 up to 1000 | ±0.3 | ±0.8 | ±2.0 | ±4.0 |

| Over 1000 up to 2000 | ±0.5 | ±1.2 | ±3.0 | ±6.0 |

| Over 2000 up to 4000 | - | ±2.0 | ±4.0 | ±8.0 |

1. Unilateral Tolerances

This type of tolerance allows one directional variation only, hence unilateral. Let’s work on a simple example. Given a shaft that needs to fit into the internal diameter of a sleeve. The shaft diameter should not exceed the sleeve’s inner diameter, so when applying unilateral tolerance on the shaft, you control it by allowing only negative variation from the nominal size (e.g., given the shaft diameter is 1.000 in, applying unilateral tolerance will look like this: 1.000 +0/-.005 in). Unilateral tolerances are commonly used in components that have mating parts.

2. Bilateral Tolerances

In contrast to unilateral tolerance, bilateral tolerances allow both plus and minus variations from the nominal size. Applying bilateral tolerance on a 1.000” dimension would look like this: 1.000 +/- .005. This type allows equal distribution of the variation permitted for the piece part. Bilateral tolerances are commonly used, but not limited to, to call out external dimensions.

3. Limit Tolerances

Limit tolerance is expressed as a range of the minimum dimension and the maximum allowable dimension. The dimension for the manufactured part should lie in between these values. Limit tolerances in manufacturing drawings will look like these: .995-1.005 in.

4. General/ Standard Tolerances

These are the standards set for the most common components in the industry like thread sizes, pin sizes, pipes, steel bars, and many more. General tolerances are usually regulated by various standards governing associations like ASME, AISI, ISO, and many more. The control and specific dimensions for these tolerances are typically listed in table references.

Some example includes:

● Calling out threads as coarse, fine, extra-fine (UNC, UNF, UNEF)

● Calling out shaft and hole dimensions as to fit tolerances like H7/g6, G7/h6, H8/g6 (in simple terms: slide fit, interference fit, snug fit, force fit, free-running fit)

Geometric Dimensioning and Tolerancing (GD&T)

This type of tolerancing uses feature control frames in depicting specific dimensional and form tolerances. This paves the way for a clearer depiction of controlling the features of the CNC parts, including flatness, straightness, runout, perpendicularity, and position callouts. GD&T is very useful for designers in specifying their required CNC machining tolerances.

What Are The Things We Need To Consider When Dealing With Tolerances?

1. Find the right machining facility partner

If you have a part you are looking to outsource, you should look for a trusted and established machining facility to be your partner. Not all CNC machining services providers have the capability to deliver extremely precise and accurate parts with tight tolerances. Facilities with the most experience and high-end equipment are at an advantage for this.

2. Maintain the accuracy of work holders

Work holders play a great part in ensuring that the CNC machining tolerances are achieved. These are responsible for holding the part in place while being machined and used as reference points regarding locations.

3. Use high-performance cutting tools

Cutting tools are one of the reasons behind the dimension variations in a work part. This may be caused by wrong cutting tool utilization, tool deflection, and dull cutting edge. Tool deflection usually occurs on long-ended features like deep holes and long shafts. Also, dull cutting tools put your parts in an undesirable position and threaten your spindles’ accuracy.

4. Material used

Dimension accuracy can be difficult to attain for some materials and might be easy for some. Take note that materials behave differently while being exposed in the machining environment.

Conclusion

● CNC machining tolerances are an important aspect of ensuring the quality and functionality of the parts produced by setting limits on up to what extent the dimensional variations are allowed.

● The application of tolerances in fabricating piece parts is important to control the cost, ensure their interchangeability, and maintain functionality.

● The most common types of machining tolerances are unilateral tolerance, bilateral tolerance, limit tolerance, general tolerance, and GD&T.

● It is also essential to consider some factors when working with tolerances. These factors include work holders, material, tooling performance, and the selection of preferred machining facility.

Search Blog

Thermoforming and Vacuum Forming

Sep. 23, 2021

Steel or Stainless What is the Most Durable Sheet Metal?

Sep. 23, 2021

8 Things You Need to Know About Anodizing Aluminum

Sep. 23, 2021

Sep. 08, 2021

Navigation

Resources

Contact Us

+86 0755 36957776

102, 41 block, No 67 Banggang Road, Dongfang Community, Songgang, Bao'an District, Shenzhen, China

Room 1508, Aran Center Office Seond Phase 15, Nathan Road 625, Kowloon, HongKong