Jan. 12, 2026

Welcome to IDEAL's ultimate guide to Powder Coating Thickness: Standards, Measurement & Best Practices. Our blog is a comprehensive resource for anyone interested in learning more about this versatile and affordable option.

When it comes to surface finishing, few factors are as overlooked yet as essential as coating thickness. In processes like anodizing or electroplating, thickness is often measured in just a few microns. Powder coating, however, typically requires much higher film builds (often 50 μm or more) to achieve its protective and decorative functions. Too thin, and the coating fails to resist corrosion or mechanical impact; too thick, and it risks cracking, peeling, or uneven appearance. This delicate balance makes powder coating thickness a decisive parameter across industries such as automotive, construction, appliances, and medical equipment.

In this article, we’ll take a closer look at why thickness matters, how it is controlled, and the standards that define quality in powder-coated products.

1. Technical Basis and Importance of Powder Coating Thickness

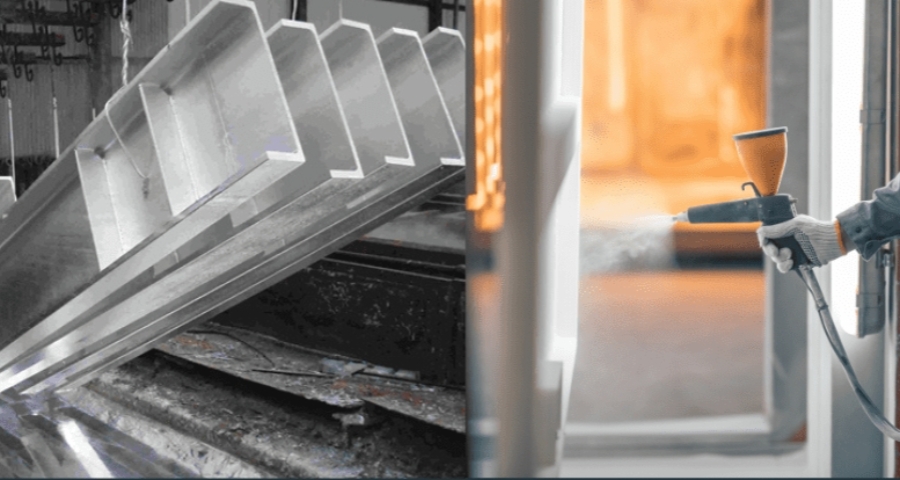

Powder coating involves applying solid powder to a workpiece surface through electrostatic attraction. Once applied, the powder is cured at high temperature to form a continuous protective film. Compared with traditional liquid coatings, powder coatings offer several advantages: no VOC emissions, high material utilization (often above 95%), and excellent coating performance.

Powder coating thickness, usually measured in microns (μm), is one of the most fundamental parameters in this process. It is determined by the density of powder particles under the electrostatic field and the cross-linking degree after curing. Thickness directly affects not only aesthetics but also coating functionality. Its importance can be summarized in three aspects:

Protective Performance

The corrosion resistance of a coating generally increases with its thickness. In outdoor architectural applications, a thickness of 60–120 μm provides effective protection against UV radiation, acid rain, and humidity. Research shows that if thickness falls 30% below design requirements, salt spray resistance can drop by more than 50%. For example, aluminum windows used in coastal areas require at least 80 μm to meet ASTM B117 standards for 1,000 hours of salt spray testing. If thickness is insufficient, defects such as blistering or peeling may occur prematurely.

Mechanical Performance

Thickness also affects adhesion, hardness, and wear resistance. A thin coating (below 40 μm) may expose the substrate when impacted, while an excessively thick layer (above 150 μm) can develop cracks due to internal stress. In automotive components, engine covers typically maintain a coating thickness of 70–90 μm, ensuring hardness above 3H and adhesion that passes ASTM D3359 testing.

Appearance Quality

Uniform thickness is essential for achieving consistent color and gloss. When deviations exceed ±10 μm, defects such as orange peel or sagging may appear. For high-end appliances like stainless steel refrigerator doors, thickness is often controlled within a narrow range of 50–60 μm to achieve a mirror-like finish with gloss levels above 85 GU (measured at 60°).

Building thickness control into your QA process early will keep coatings performing and looking as specified.

2. Key Factors Affecting Powder Coating Thickness

Several variables influence the final coating thickness:

Powder Type

Epoxy powder (50–80 μm): Commonly used for indoor applications where corrosion resistance is important but UV exposure is limited.

Polyester powder (60–120 μm): Offers strong weather resistance, making it suitable for outdoor components such as architectural panels or fencing.

Fluorocarbon powder (80–150 μm): Designed for environments requiring high durability, such as curtain walls and aluminum profiles in construction.

Application Method

Electrostatic spray: Allows precise thickness control, usually in the 50–120 μm range. It is widely adopted in industries that need both protection and a smooth appearance.

Fluidized bed coating: Produces much thicker layers, ranging from 100 to 500 μm, and is typically used for heavy-duty corrosion protection, such as pipelines, valves, and structural steel.

Substrate Characteristics

The surface roughness and pretreatment process (e.g., phosphating or chromating) directly affect powder adhesion.

Complex geometries, such as deep grooves or sharp corners, may lead to uneven distribution, creating areas that are too thin or excessively thick.

Curing Conditions

Correct curing is essential for achieving the intended thickness and performance. If the temperature or curing time is insufficient, the powder may not fully melt or cross-link, leading to weak adhesion, poor durability, and inaccurate thickness measurement.

Choosing the right powder and matching it to both substrate and curing profile is often more critical than the spray technique itself.

3. Methods for Measuring Powder Coating Thickness

Accurate measurement is essential to maintain quality. Common techniques include:

Dry Film Thickness Gauges

The most common nondestructive option.

Magnetic gauges work on steel substrates by detecting changes in magnetic flux.

Eddy current gauges are used on non-ferrous metals like aluminum and copper, providing quick and reliable readings.

Ultrasonic gauges go a step further, capable of assessing multilayer coatings and irregular geometries without damaging the part.

Cross-Section Microscopy

When absolute precision is required, samples can be cut and analyzed under a microscope. This destructive method offers direct visual confirmation of thickness but is usually limited to laboratory or certification testing due to its time and cost.

International Standards

Measurement practices are standardized to ensure global consistency.

ISO 2178 for magnetic substrates,

ISO 2360 for non-magnetic substrates,

ASTM D7091 as a widely accepted industrial reference.

Measuring Points

Even the most advanced gauge is only as good as the sampling strategy. According to ISO 2808, the number of points depends on the workpiece size:

100 cm² → at least 3 points

100–1000 cm² → 5–9 points

1000 cm² → add 2–3 points for every extra 1000 cm²

To ensure representative data, points must be evenly distributed and positioned away from edges (≥5 mm), welds, and sharp corners where readings can be distorted.

4. Industry Standards and Practical Reference for Powder Coating Thickness

Powder coating thickness requirements come from two directions: official industry standards, which define the minimum acceptable levels, and practical reference ranges used in everyday production. Combining both perspectives helps ensure coatings not only meet certification needs but also perform reliably in real-world application.

| Application Area | Standard / Reference | Typical Thickness Range (μm) | Key Purpose |

|---|---|---|---|

| Construction (windows, curtain walls) | QUALICOAT: local ≥60 μm, avg ≥70 μm AAMA 2604: ≥60 μm | 60–70+ | Weather resistance, UV stability |

| Automotive | Internal OEM specs / production practice | 50–90 | Durability, chip resistance |

| Appliances | Manufacturer guidelines | 60–100 | Corrosion protection, appearance |

| Medical Equipment | ISO 10993-related standards Production reference | 30–100 (40–60 for surgical tools) | Biocompatibility, sterilization resistance |

| Heavy Industry | Custom engineering specs | 100–300 (up to 500) | Extreme corrosion and wear protection |

| General industrial parts | Common reference values | 10–60 | Small hardware, internal appliance parts |

| Decorative parts | Common reference values | 40–80 | Furniture accessories, appliance exteriors |

| Outdoor protection | Common reference values | 60–120 | Railings, lighting poles, containers |

In most cases, a 60–80 μm range strikes a balance between protection, adhesion, and appearance. However, final targets should always be adjusted according to the product’s environment, durability needs, and any applicable industry standards.

5. Optimizing Powder Coating Thickness for International Requirements

To meet global standards, manufacturers often implement:

Strict Pre-treatment

Before powder application, proper surface preparation is essential. Degreasing removes oils and residues, phosphating enhances adhesion, and passivation protects the substrate from corrosion. These steps help achieve uniform coating distribution and reduce the risk of defects such as thin spots or peeling.

Automated Application

Manual spraying can introduce variability, especially on complex shapes or large batches. Robotic systems standardize spray speed, gun distance, and coverage, minimizing human error and improving repeatability across multiple parts.

Real-time Monitoring

Inline thickness measurement systems provide immediate feedback, allowing operators to adjust parameters on the fly. By continuously monitoring coating thickness, manufacturers can prevent deviations before they affect large production runs, ensuring every part meets the required specification.

Third-party Reports and Certification

For international clients, verification is often as important as actual performance. Certificates from accredited organizations such as SGS or TÜV confirm that coating thickness and overall quality comply with ISO or ASTM standards. Providing these reports not only supports regulatory compliance but also builds customer confidence in the product’s durability and performance.

Meeting international requirements often comes down to the details—how well each surface is prepped, the consistency of the spray, and trust in the verification process.

6. Common Problems and Solutions

Even with careful planning and advanced equipment, issues with powder coating thickness can still occur.

Coating Too Thin

A layer that is thinner than intended can compromise corrosion protection and durability. Causes often include excessive spray distance, insufficient electrostatic voltage, or too little powder applied. The solution is to adjust spray gun settings, increase powder flow, and ensure proper coverage, especially on complex shapes.

Coating Too Thick

Excessively thick coatings can lead to defects like sagging, orange peel, or internal stresses that cause cracking. This often happens when the spray speed is too slow or the gun is held too close to the surface. Optimizing the spray path and increasing line speed helps maintain a uniform, controlled thickness.

Uneven Thickness

Variations across the part can reduce both protection and visual quality. Poor substrate conductivity or incorrect spray angles are common culprits. Improving surface pre-treatment and adjusting gun movement and angle can significantly enhance uniformity.

Insufficient Coverage (Faraday Cage Effect)

Tight corners or recesses may receive less powder due to the Faraday Cage effect. Specialized corner-enhancement guns and reducing the main gun voltage to 50–60 kV can help powder reach these difficult areas without over-applying on flat surfaces.

Large Thickness Deviations

Variations between different areas of the same part, or between parts, often result from conveyor speed fluctuations or unstable powder flow. Implementing servo motor control to maintain speed variations within ±0.1 m/min ensures consistent coating across the production line.

Cracking Due to Excessive Thickness

Overly thick single layers (>100 μm) or improper curing can lead to fine cracks or even peeling after curing. Applying multiple thin coats (<50 μm per layer), optimizing the curing cycle, and adding elasticity agents to the powder formulation can prevent cracking while maintaining the desired protective properties.

Even with advanced systems, hands-on attention to spray angles, layer sequence, and curing cycles makes the biggest difference in consistent results.”

Conclusion

Powder coating thickness is a key factor that determines a coating’s durability, protection, and visual quality. Achieving the right thickness requires careful consideration of material type, component geometry, and application method—especially for CNC-machined or sheet metal parts with complex shapes or thin sections.

For more information on Powder coating thickness, explore our range of polycarbonate bushings for truck to find the perfect fit for your vehicle. Need assistance with choosing the right material? Check out our Guide for detailed insights.

Previous: Aluminum Extrusion Design Guide

Next: None

Search Blog

Hey there, I'm Abby!

At IDEAL RAPID PRODUCTION, I'm a Project Management Expert in custom manufacturing field for more than 15 years. We offer cost-effective machining services from China. Ask for a quote for your ongoing or upcoming projects now!

Aluminum Extrusion Design Guide

Dec. 29, 2025

GET IN TOUCH WITH US

Navigation

RESOURCE

Contact Us

Tel: 0755-36957776

E-mail: info@idealrp.com

Skype: +86 135 2877 3620

Whatsapp: +86 135 2877 3620

Add.: Shenghua Building, Songgang, Bao'an,Shenzhen 518105

Add.: Room 4, 16/F, Ho King Commercial Building, 2-16 Fa Yuen Street, Mong Kok, Kowloon, Hong Kong